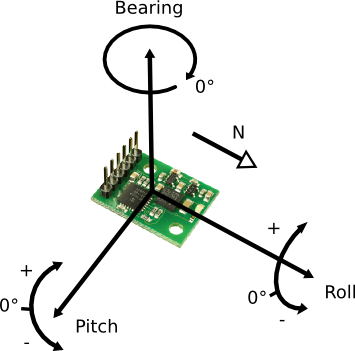

The CMPS10 module is a tilt compensated compass. Employing a 3-axis magnetometer and a 3-axis accelerometer and a powerful 16-bit processor, the CMPS10 has been designed to remove the errors caused by tilting of the PCB. The CMPS10 produces a result of 0-3599 representing 0-359.9 or 0 to 255.The output of the three sensors measuring x, y and z components of the magnetic field, together with the pitch and roll are used to calculate the bearing, each of these components are also made available in there raw form. We have also written examples of using the CMPS10 module with a wide range of popular controllers. The CMPS10 module requires a power supply at 3.3 - 5v and draws a nominal 25mA of current.

There are three ways of getting the bearing from the module. A serial interface, an I2C interface or a PWM output.

The Factory use pin is for our internal testing only, this pin should remain unconnected.

Data update frequency

Updates of the tilt compensated heading occur at 75hz with the data is filtered by means of a 45 sample buffer, this means a complete refresh of the buffer is achieved every 640ms. Raw data from the magnetometer and accelerometer is available every 13.3ms.

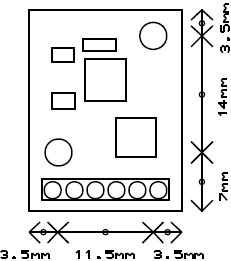

PCB Drilling Plan

The following diagram shows the CMPS10 PCB mounting hole positions.